Locomotive Operations

There’s much more to operating locomotives than can be presented in a small display. And the art and science of train handling are broad subjects themselves. But the following will help you find more information, depending on your own interests.

First, some basics. In steam locomotives, basically the engineer operated the throttle, the reverse lever, and the brakes in response to track conditions, company rules, and other factors. The fireman made sure the boiler was adequately supplied with water and the firebox with fuel. He maintained adequate steam pressure and proper conditions in the firebox and in the flues that carried hot combustion gases through the boiler. On the western parts of the Southern Pacific Railroad, after about 1900, locomotive fuel was nearly always oil, not coal. The fireman usually took care of adding water and oil to the tender at intermediate stops, while shopmen handled that task at major terminals. The engineer and the fireman were jointly responsible for observing trackside signals and for following train order instructions, though the conductor was ultimately in charge of the train’s progress along the line. For passenger trains, the conductor rode in a passenger car, usually had a reserved space to work, and sometimes was assisted in checking tickets and helping passengers by one or more assistant conductors. For freight trains, the conductor rode and worked in the caboose. In the steam era, passenger trains often had, and freight trains nearly always had, one or more brakemen who helped with any coupling or uncoupling of cars and locomotives and operating of track switches along the line. Sometimes a head brakemen (meaning at the front of the train, not in charge of other brakemen) also rode in the locomotive cab.

Diesel locomotives obviously required less attention to fuel and water than steam locomotives. However, early diesels lacked most of the automatic features that were incorporated later, so the fireman still helped monitor conditions and, in the case of most passenger trains into the 1970s, tended a small boiler that provided steam heat. Diesel-locomotive firemen were often in effect engineers-in-training, and continued to provide a second set of eyes and ears for safety.

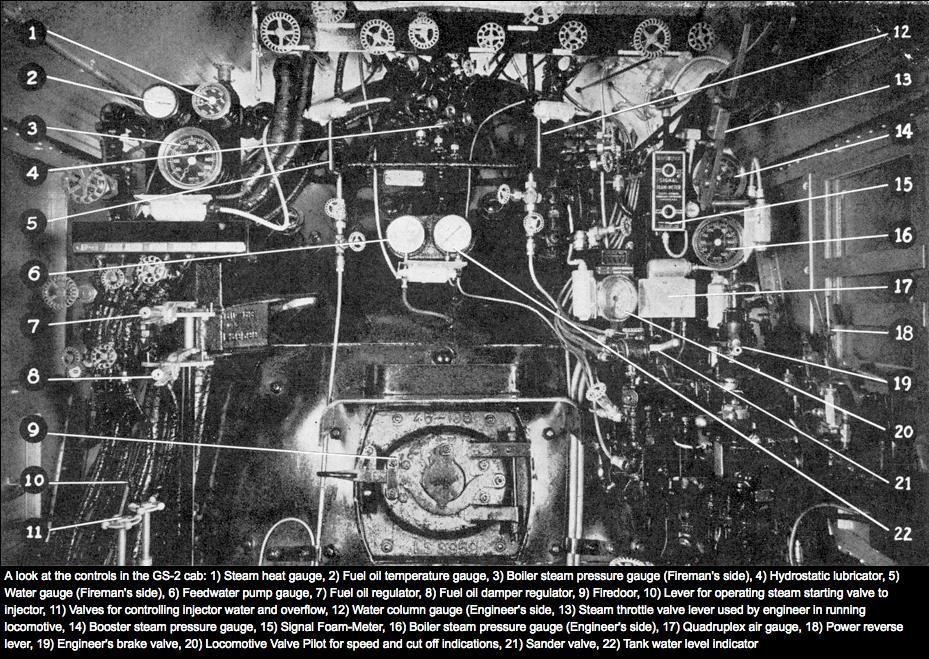

Here is an illustration of a Southern Pacific GS-2 locomotive backhead, the part of the firebox and boiler that extended into the cab, with many features labeled. The windows that allowed views ahead are not obvious, but they were to the right and left of the backhead. While the arrangement of basic controls was similar among the many types of steam locomotives, details varied widely between types, among classes of the same type, and even within classes depending on when they were rebuilt or reactivated as preserved, heritage locomotives.

Later steam locomotives had steam-driven generators (turbine type) to provide electricity for headlights, classification lights and number boards, and cab lights. Steam-driven compressors (piston type) provided compressed air for the brakes. The automatic-brake applied to the train’s cars. It was automatic only in the sense that if the continuity of the pressure line extending along the train was interrupted, the brakes applied automatically. The “independent” brake applied to the locomotive driving wheels and the tender wheels. Depending on the length and distribution of weight in a train, and the profile of the track (sloping up, down, or both) under the train, the engineer used the throttle and the two types of brakes to control speed and the behavior of slack, the tendency of a string of cars to bunch together or stretch out due to the individually small but cumulatively significant spaces in the couplings.

The same train-handling principles apply to diesel-electric locomotives. But most diesels used in over-the-road service (as opposed to switching in a limited area) also have “dynamic” braking. Dynamic braking uses the electric motors, which actually power the wheels, as generators; electrical resistors dissipate the loss of movement energy as heat. In air brakes, the movement energy is also shed as heat, but via the brake shoes and wheels, which can be problematic on long, downhill grades. Before dynamic brakes, trains often had to stop to cool their wheels before reaching the bottom of a long, steep grade. Another advantage of diesels is that individual locomotive “units” can be combined into a single locomotive that is operated by one engineer in one cab, by way of electrical cables between the units.

Steam locomotives had many exterior moving parts that required lubrication. Some points were lubricated by the fireman and engineer walking around with oilcans and applying oil directly when the locomotive was stopped. Some points also had small reservoirs that could hold oil and release it gradually. Still other points used special types of grease that were injected using guns connected to the compressed air supply.

In diesel locomotives, the fuel also lubricates the interior engine parts.

Here are links to some videos on operating locomotives. These videos are not provided by the San Luis Obispo Railroad Museum, which does not endorse their content or any associated advertising or further links.

Operating a Steam Locomotive

Animated Steam locomotive linkage system

Operating a diesel locomotive part 1